The Aldridge-Benge Firefighter Safety Act of 2008

|

|

In December 2009, the Florida legislature unanimously passed the Aldridge-Benge Firefighter Safety Act (Florida Statute 633.027), a law that requires the identification of commercial, industrial, or multi-unit residential buildings that contain light-frame construction.

The law is named after two Orange County, Florida, firefighters, Todd Aldridge and Mark Benge, who lost their lives in a 1989 gift shop fire following a collapse of the lightweight trusses.

Efforts to pass this legislation were made a higher priority following the deaths of nine firefighters in Charleston, South Carolina.

The Aldridge-Benge Firefighter Safety Act of 2008

The law requires owners of building that contain light-frame construction to apply markings to the building exterior. The required marking is an 8″ Maltese cross that includes one of the following:

Structures with light-frame truss roofs shall be marked with the letter

“R.”

Structures with light-frame truss floor systems shall be marked with the letter “F.”

Structures with light-frame truss floor and roof systems shall be marked with the letters “RF.”

What Is Light-Frame Construction?

Light-frame (or light-weight) construction is a broad definition of newer types of construction that have become more popular since the 1950s.

The goal of light-frame construction is reduced cost of building materials, faster build time, and reduced cost to the buyer.

It is important to understand these construction methods in order to understand what is actually covered (and not covered) by the new law.

|

|

Most light-frame forms of construction are based on the truss.

Trusses take advantage of the strength of the triangle, and trusses have largely replaced traditional wooden joists/rafters in floor and roof assemblies, and steel I-beams in commercial buildings.

Trusses also offer the ability to span large areas creating an uninterrupted floor space free of supporting columns.

Nowadays, trusses (and other lightweight components) are designed by computer programs and built off-site to exacting standards and dimensions, then delivered to the building site.

Light-frame construction has long been recognized by the fire service for the potential danger of premature collapse.

While light-frame construction meets or exceeds industry standards for strength and durability, these buildings can become unsafe for interior firefighting much faster than buildings that use more traditional building components.

Of the five basic types of construction, lightweight components can be found within these three:

- Type II – Non-Combustible

- Type III – Ordinary

- Type V – Wood Frame

Note: Type 1 construction (Fire Resistive) may contain lightweight components but these are “protected” by a membrane or fire-resistant coating. For this reason Type 1 buildings present a reduced collapse risk when compared to Types II, III, and V.

|

Type II — Non-Combustible |

Most commercial buildings (excluding high rises) use Type II construction, most commonly masonry walls with steel roof assemblies.

| Ordinary Construction |

Type III — Ordinary

These buildings can be single or multiple story, and are often referred to as “taxpayers” or “brick and joist” buildings.

Masonry walls with wood floors define this construction type.

Modern Type III uses light-frame wood instead of traditional joists or

tongue and groove planking.

|

Type V — Wood Frame |

Buildings where the frame is entirely wood, although the exterior can be wood, stucco, block, or brick veneer.

This not only includes single-family dwellings but apartments, townhouses, condominiums, and some hotels up to four stories in height.

Forms of Light-Frame Construction

Wood Trusses

Repetitive wood trusses are more commonly used instead of the more traditional solid wood.

While a joist or rafter is a solid wood member (2 x 8, 2 x 10, 2 x 12)

with considerable mass, truss elements are smaller in size (usually 2×4) and have an open web configuration. The wood members are usually connected with metal truss plates (commonly called gusset plates).

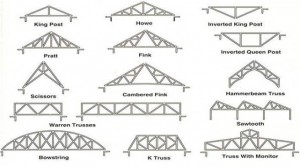

There are several truss designs (see chart) and they can be used as floor or roof assemblies.

However, all trusses are not necessarily lightweight. Heavy timber trusses such as the bowstring truss use heavier wood members

although these are far less common in Jacksonville.

|

|

|

|

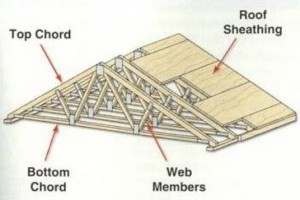

All trusses have top chords, bottom chords, and web members.

When used in floor or flat roof assemblies, trusses also eliminate the horizontal fire separation previously found when solid wood components

were used.

This permits unchecked fire spread within the truss assembly.

|

|

Steel Trusses

These are commonly referred to as “bar joists” but the proper

term is “open web steel truss.”

These can be built using light gauge to heavy gauge steel, and may often contain simple angle iron for the top and bottom chords and rebar for the web members.

Steel trusses are very common in Jacksonville, mostly in mercantile buildings such as convenience stores, strip malls, industrial buildings, and large anchor stores such as Lowes or Wal-Mart.

While steel is a very strong building material, fire can weaken steel prematurely to the point of collapse.

Steel begins losing strength at temperatures lower than actual flame temperatures.

A significant load above the steel framing (such as air handlers or accumulated rainwater) can further weaken the structure.

Engineered Wood

This includes a very broad variety of building materials and their use

has increased in the past two decades.

Engineered wood uses wood products and industrial adhesives to make engineered wood in the shape (and strength) of traditional lumber.

Plywood is a form of engineered wood that has been in common use in the U.S. Building industry for well over 100 years.

One major concern about engineered wood is the performance of adhesives under fire conditions. While independent testing of these adhesives confirms their strength, the fire service remains skeptical.

| Engineered Wood – OSB; LSL; LVL |

In the quest for less expensive wood products, the following engineered woods have been developed:

- Oriented strand board (OSB)

- Laminated strand lumber (LSL)

- Laminated veneer lumber (LVL)

OSB and LVL have replaced plywood in many building applications, while LSL is used to make beams for headers, lintels, and other load-bearing components.

|

|

One type of engineered wood product deserves special attention — the wooden I-joist.

This combines the appearance of a joist with the chord design of a truss — it contains a top and bottom chord made of 2×3 or 2×4 lumber or engineered wood, with a web of relatively thin OSB.

Like all engineered wood products, these meet industry standards for strength but have been identified as the cause of premature collapse in several recent fires nationwide.

Due to the thin web component, burn-through is rapid, thus sacrificing

the bottom chord and precipitating collapse.

|

|

Steel Beams

We are all familiar with the strength and mass of the traditional steel

I-beam. Steel is also used in fire-resistive construction (Type I) to reinforce concrete.

However, a lighter form of steel construction has been developed that can be used in place of the open web steel truss. These are called “C” or “Z” beams depending on their shape (sometimes called “purlins“).

They contain considerably less mass than I-beams and are therefore more susceptible to weakening when exposed to fire.

Expect these beams to weaken much like an open web steel truss.

|

|

Composite Trusses

These use a combination of wood and steel. There are many variations.

Most often wood is used for the chords and light gauge steel or tubing used for the webs.

The photo here shows a truss plate incorporated into the metal web members.

What Construction Is Covered by the Law?

Now that we have a better understanding of light-frame construction, let’s take a closer look at the specifics of the Aldridge-Benge Firefighter Safety Act. The original wording is contained in Florida Statute 633.027, with a subsequent Florida Administrative Code to provide direction in implementation.

Here are the major components of the Florida Administrative Code:

“The purpose of this rule is to require the placement of an identifying symbol on structures constructed with a light-frame truss component in a manner sufficient to warn persons conducting fire control and other emergency operations of the existence of light-frame truss-type construction in the structure.”

“Light-frame truss-type construction” means a type of construction

whose primary structural elements are formed by a system of repetitive wood or light gauge steel framing members.”

The definition above has created confusion within the fire service, code enforcement agencies, and the building industry. While the wood truss is clearly identified, other forms of lightweight

construction are not as clearly included despite the intent of the original law.

|

|

In 2010, Chief Financial Officer and State Fire Marshall Alex Sink issued a declaratory statement in an effort to clarify the definition of light-frame construction. This statement specifically excluded lightweight steel construction including the open web steel truss and the C/Z beam.

It is still unclear if the wooden I-joist meets the requirements of the

law.

In response to this, the Florida Fire Marshals and Inspectors Association (FFMIA) has proposed additional legislation that clearly defines light-frame construction.

If this legislation is approved, all forms of light-frame construction described in this lesson will be included in the law.

Marking Requirements

|

|

You may have already seen these signs appearing on buildings in your response

district.

They are required to be a minimum of 8 inches in diameter, must be located between 4′ and 6′ from the ground, and located within 24″ to the left of the main entrance.

Additionally, if the building is longer than 100′ or contains multiple

tenants (such as a strip mall) multiple signs may be required.

What Every Firefighter Must Know!

This law can be a beneficial tool for firefighters when evaluating a structure prior to interior attack. However, every firefighter must understand the weaknesses of the law in its current form. As stated previously not all forms of light-frame weight construction are currently addressed by the law.

This law also specifically exempts some buildings.

Any multi-unit residential building (apartment complex or condominium) with three units or less is not required to identify light-frame construction.

Townhouses are also excluded (a townhouse is a connected residential building that has a two-hour fire separation between units).

And keep in mind that single-family dwellings are the largest user of light-frame construction and the majority of firefighter fatalities occur in single-family dwellings.

|

|

Summary

To summarize, it appears that the intent of the original legislation has

fallen short. While many buildings will be marked in accordance with the law, it will take time to fully comply, and further interpretation may be forthcoming as Florida fire service leaders recognize the inherent weakness of the law and pursue additional legislation.

It is incumbent upon each company officer, incident safety officer, and

chief officer to continue to rely upon pre-planning, training, and experience to identify buildings that contain light-frame construction, and make every effort to continuously evaluate the safety of operating within these buildings.

While the presence of a light-frame marking may aid in identifying light-frame construction, the absence of such a marking does not guarantee that the building is free of light-frame components.

|

|